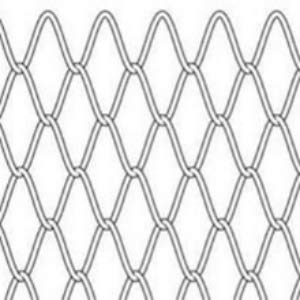

Chain link conveyor belting consists of interwoven successive spiral wire, which looks like chain link fencing. This universal conveyor belt is the simplest wire belt but functional and economical in conveying light-duty applications. Owing to its large open area, chain link belt makes itself an ideal choice for drying, cooling and heating where energy efficiency is the most important.

Belt Types

chaink link fence without rod reinforced

chaink link fence without rod reinforced

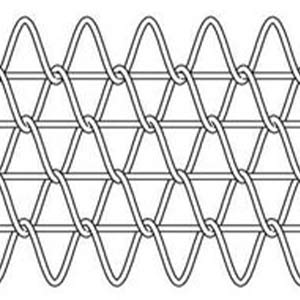

chain link belt with rod reinforced

chain link belt with rod reinforced

Rod reinforced chain link belt are more stronger than conventional chain link belt as a result of the cross rods through the interconnecting spiral wires. Not only does the rods add strength to the belt, but also make the belt stable during conveying.

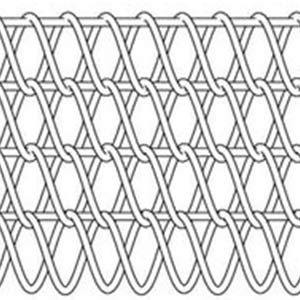

Chain Duplex Link Belt With Rod Reinforced

Apart from the standard rod reinforced chain link belt, there is also duplex Link Belt With Rod Reinforced, which has double interwoven spiral wires. This duplex version chain belt has smaller open area and more strength. Compared with universal chain link belt, rod reinforced chain link belt has wider applications because of its relatively heavy load ability, open area and economical cost.

Edge Availability

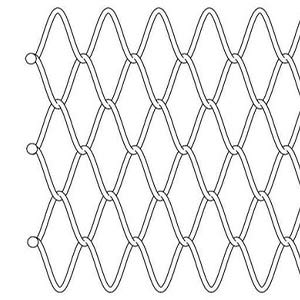

At the belt edges the coil wires are looped together and welded. This is the most common and economical edge finish. This type of edge finish allows for relatively smooth finish to the belt edge and is the most economic version of this belt style.

Knuckled Edge

The end of each coil wire is bent back into a ‘U’ shape and then interlock with the adjacent coil. The ‘U’ form is then closed securely to form a permanent link with the next coil. This formation also allows greater flexibility of the belt edges and minimises stress build up at these positions.

Chain Edge

Chain link conveyor belt are available in different edge styles including welded, knuckled and chained. Other special edge finish is available on request.

welded edge

welded edge

Along with the mesh edge finishes these meshes can be driven by side chains using cross rods which are located through the mesh coils and then through chains at the edges of the mesh.

Specifications

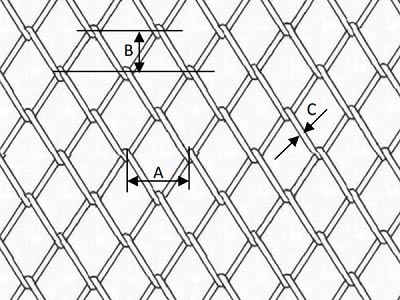

Specifications of Chain Link Belt Without Rod Reinforced

These are designed to suit the customer requirements but in general are available in lateral coil wire pitches varying from 5.08mm to 25.4mm, combined with a variety of wire diameters and longitudinal pitches to suit the application.

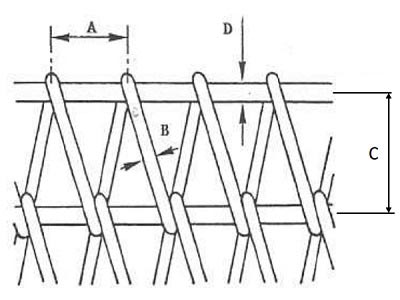

Specifications of Chain Link Belt With Rod Reinforced

C: Longitudinal Cross Wire Pitch (mm) D: Cross Wire Diameter (mm)

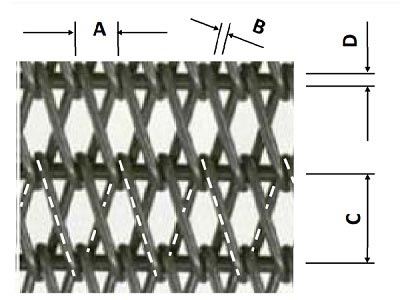

Specifications of Chain Duplex Link Belt With Rod Reinforced

C: Longitudinal Cross Wire Pitch (mm) D: Cross Wire Diameter (mm)

Contact: Grace Zhao

Phone: +86-18678082051

Tel: +86-15076828370

Email: info@wiremeshnet.com

Add: 200 Meters South of Jianzhaozhuang Village, Anping County